EOMONIT BAST

Through the Basque Government’s SPRI-HAZITEK Programme, LUMIKER has begun the development of an innovative system for structural health control and wind turbine blade pitching.

Goal

The main objective of the project is the development of a new optical monitoring system specifically designed to monitor the structural health and pitch of wind turbine blades, combining sensors and data acquisition hardware to provide high-frequency real-time measurements.

The solution

The solution will consist of a low-power optoelectronic interrogator, suitable for operating over an extended temperature range, and a set of Fiber Bragg Grating (FBG) sensors.

The system will consist of Fiber Bragg Grating (FBG) voltage and temperature sensors with implantation at the root of the wind turbine blades.

News

The main objective novelty of the project is the incorporation of the following functionalities:

- Monitoring of the torsion, bending and general loads of the wind turbine blade for the analysis of its structural integrity and remaining life;

- Monitoring of the lightning evacuation conductor by optical fiber;

- Monitoring of the pitch management of the position of the rotor blades with respect to the wind.

Optical technologies have become a powerful choice for demanding environments, such as those found in multi-watt wind turbine generators. Due to its intrinsic characteristics, Fiber Bragg Grating (FBG) sensor technology perfectly meets the following wind turbine structural and condition monitoring requirements:

- Multiplexing different parameters into a single string

- Immunity to EMI/lightning and electrical insulation

- Scaling capacity during sheet manufacturing

- Signal integrity

Fiber optic sensors and interrogators are optimized for measurement applications with high load cycles, long detection networks, or those requiring ray resistance.

The execution of this project will make LUMIKER a leader and reference at European level, and even worldwide, in advanced technologies for wind O&M through an optical monitoring solution that responds to the needs of the sector.

The project also involves collaboration with the Center for Aeronautical Technologies of Miñano, for the testing and validation of the new solution. Validation that will be very useful for:

- Assess the application of the same system in the Aeronautical sector

- Perform tests and replacement of FTI Traditional Flight Instrumentation with fiber optic sensors of greater resilience and lower weight

- Lower installation cost.

FLOAT&M

LUMIKER collaborates as a leader in component monitoring systems of Offshore Wind Turbines in the FLOAT&M project.

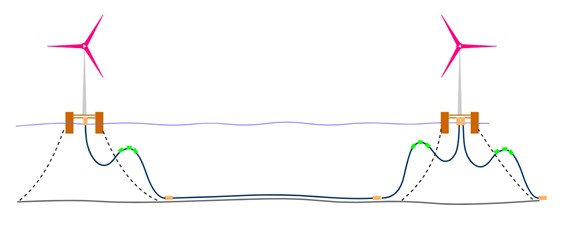

This project proposes the development of technologies, products and services to provide an integral solution for the O&M of Floating Wind through the Development of New Technologies, led by SAITEC OFFSHORE TECHNOLOGIES.

Context

Floating offshore wind is an incipient sector with great prospects of becoming one of the most relevant markets for renewables, however, having floating foundations means facing new technological challenges not only in the design of the platform and the rest of the systems, but also in the management of assets throughout their life cycle. In this sense, this HAZITEK focuses its efforts on promoting the collaboration of Basque companies for the development of new products, services and methodologies applicable to the operation and maintenance of floating wind turbines, so as to strengthen the position of the Basque Country as a world reference in the sector.

What is LUMIKER’s role in this context?

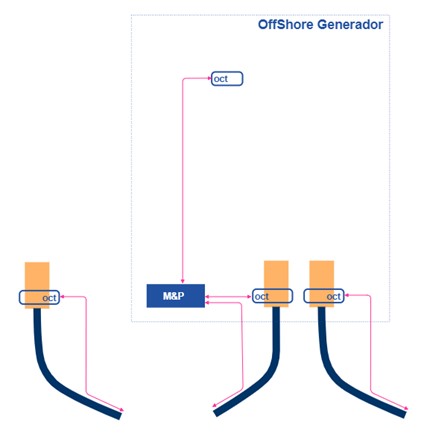

Specifically, LUMIKER’s role is the integration of measurement technologies with fiber optic sensors in collaboration with DITREL, TECNALIA, and NAUTILUS to:

The sound of pre-connectors of inter-array cables for the extraction of thermal and mechanical data and enable the development of digital twins that allow to improve their designs, anticipate faults and reduce their costs.

The development of distributed fiber optic monitoring technologies by means of brillouin phenomenon of high performance and low cost BOTDA type, for the analysis of voltage, displacements and voltage of inter-array cables of several km in length between different wind turbines of an offshore park with the following characteristics:

- Deformation resolution capacity of 25 microstrain.

- Spatial resolution capacity of 2 meters.

- 1Hz real-time capability.

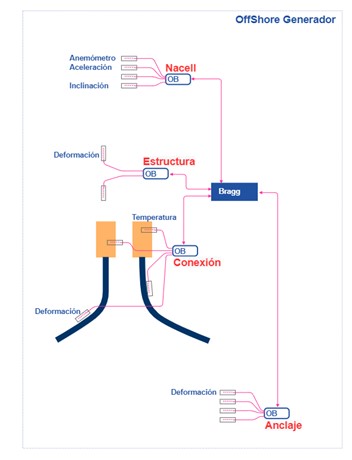

Development of a Monitoring and Supervision System, or Condition Monitoring System (CMS), for floating wind turbine platforms (FOWT). It is about implementing a series of measures through sensors, data acquisition systems and communications, which allow the FOWT to be monitored, with the aim of ensuring its integrity, characterizing its operation, and preventing failures. The main objective of full-scale sea trials is to validate the technical feasibility of the technology developed by NAUTILUS.

To do this, it is necessary to know how it behaves in different operating conditions of the wind turbine and under different wave conditions. These parameters will serve to know the real loads to which the floating platform is subjected, and thus be able to validate the simulation models and design considerations as the safety factors considered.

In addition to defining all sensor systems, LUMIKER will define the data acquisition system and communications necessary to be able to collect and transmit all the information from the floating platform.

LUMIKER collaborates with NAUTILUS in this task by designing a Bragg system that allows the monitoring of different variables, necessary or critical within the wind turbine.

Preliminary outline

If you want to know more about EOMINT BAST and FLOAT&M visit us at Wind Europ Annual 2022 at the BEC – Bilbao Exhibition Centre on 5, 6 and 7 April. Do not miss this opportunity and register by accessing the following link: https://windeurope.org/annual2022/registration/