What is CAMOS?

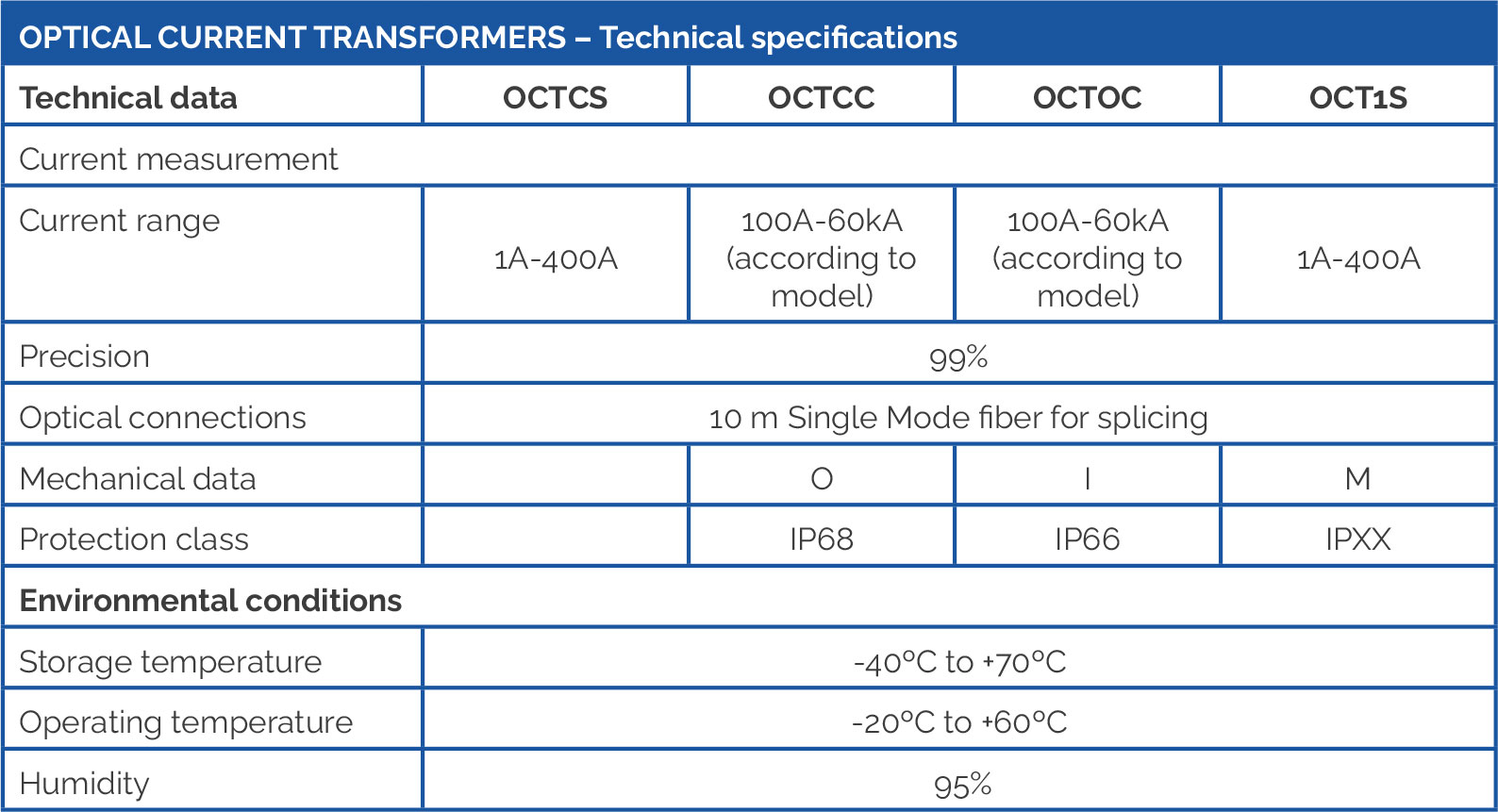

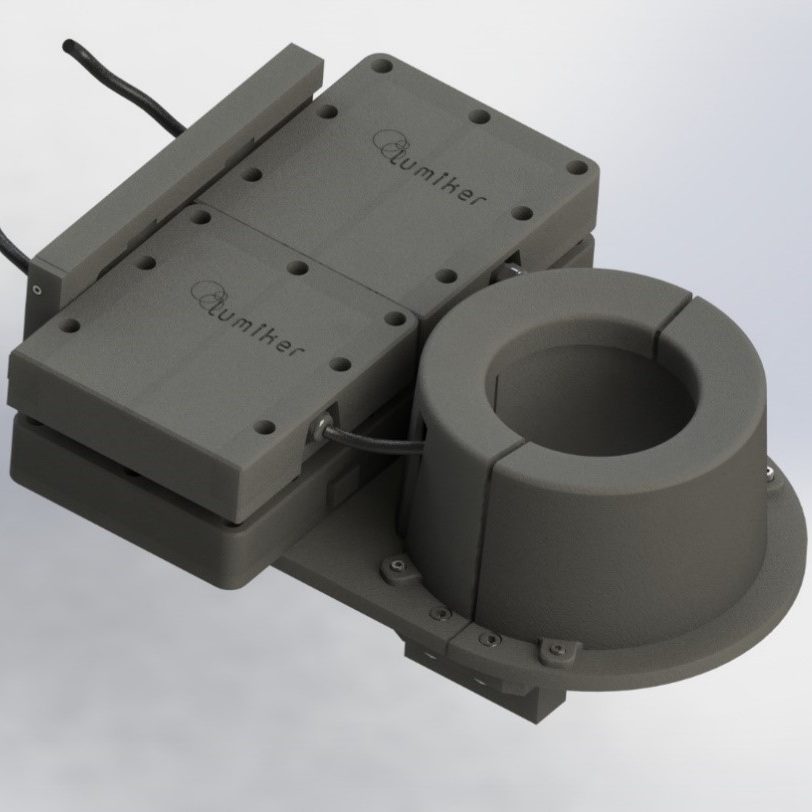

CAMOS (Cable Advanced Management Optical System) is a technology patented by LUMIKER that is made up of several optical sensors (Optical Current Transformers – OCTs) for the complete management of power cables.

The system monitors in real time (24/7) the most important values of the cable in modules and phase:

The CAMOS system can integrate BRAGG measurements of temperature or strain.

LUMIKER optical systems are passive (they do not require current or maintenance), and can measure nominal values (2A to 600A) and short-circuit values (up to 60,000A).

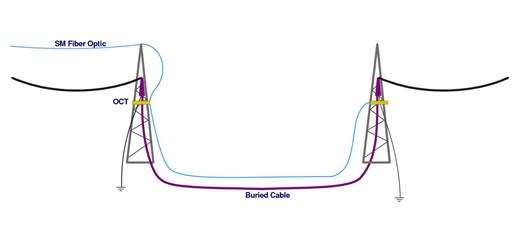

Optical systems can be located at substations and also at intermediate points (e.g. ground connections).

What CAMOS has to offer

Discover the advantages of our Cable Management Optical System

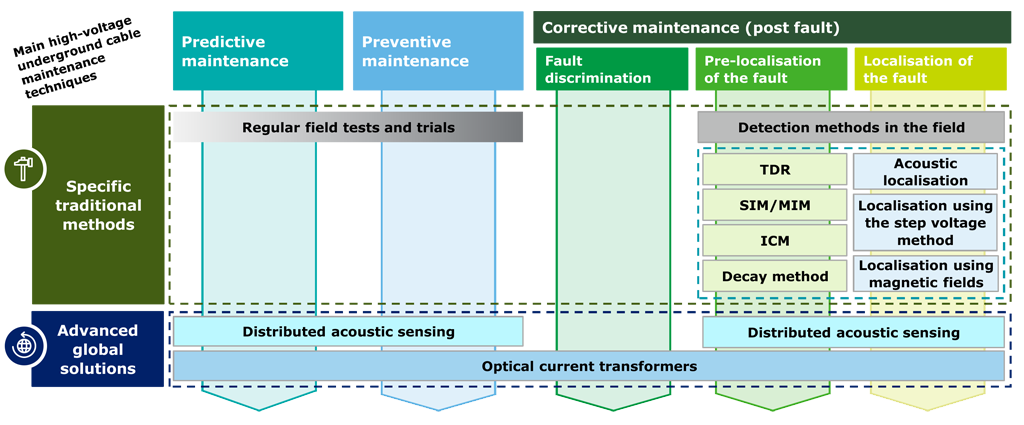

UNDERGROUND CABLE MAINTENANCE

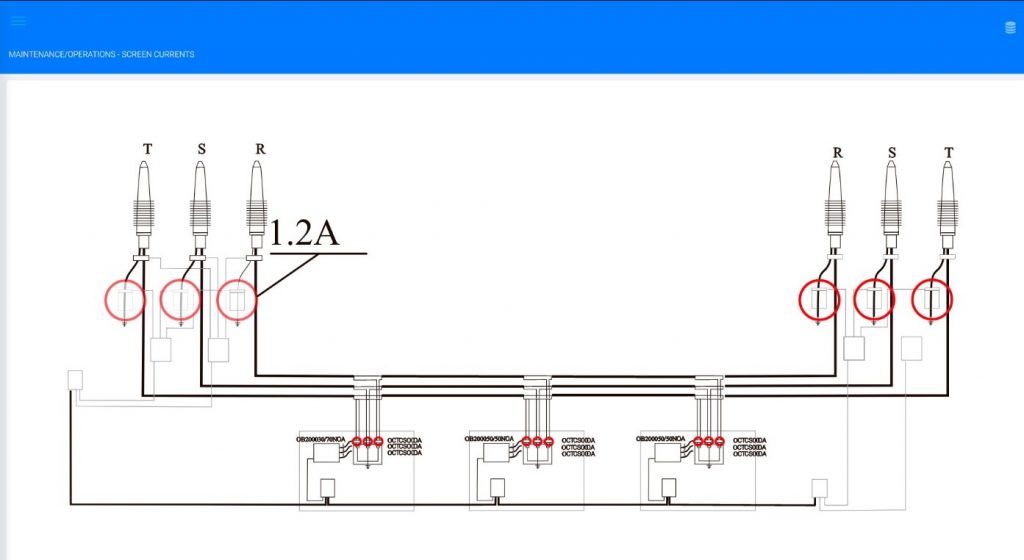

In underground cables the maintenance process is very limited, since the crosslink and grounding boxes are usually buried and access is generally not easy. The currents that flow through the grounding system are, without a doubt, clear indicators of the health of the insulation of the cable.

In addition, the magnitude and angle measurement of the current gives a complete picture of the state of the cable system and the environment in which it is located. These allow the engineer to make a useful comparison with what is to be expected based on the initial design.

By measuring the currents in the CAMOS system, it is possible to identify deviations in the installation in real time, or work on its data to improve the health of the installation by improving operations and extending the life of the cable.

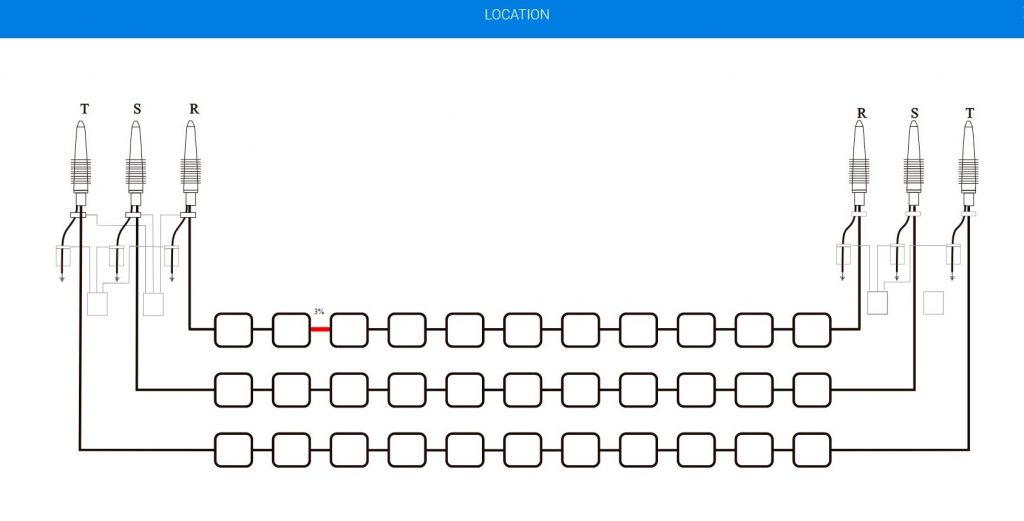

UNDERGROUND CABLE FAULT LOCATOR

The location of faults in cables is a very complex task and, once it happens, there are great losses for electricity companies and their customers. In underground installations, it becomes more complex to take measures and to deduce where the fault has occurred, as well as to be able to solve the problem in the shortest possible time.

The CAMOS system has its own algorithms. Once the fault has occurred, they deduce, in real time, the phase in which the fault has occurred, the section between the groundings and, in the case of transposition cables, the exact point of failure. And all this, based on the short-circuit values of the installation.

FAULT DISCRIMINATION IN MIXED LINES

In lines with areas that work both overhead and underground, CAMOS provides line and screen differential protection (87L/87S), which allows segregating where the fault has occurred. To do so, CAMOS uses a set of OCTs located at the terminal points of the underground sections.

The CAMOS fault discriminator acts on the protection relay. If the fault affects the aerial section, it automates the closing of the system. However, if it is detected in the underground section, the discriminator blocks the reclosing to locate the fault.

The discrimination system is capable of managing long-distance lines (100 km) with several aerial and underground sections, thanks to the integration of an EDFA amplifier integrated in the interrogator.

Return of Investment (ROI)

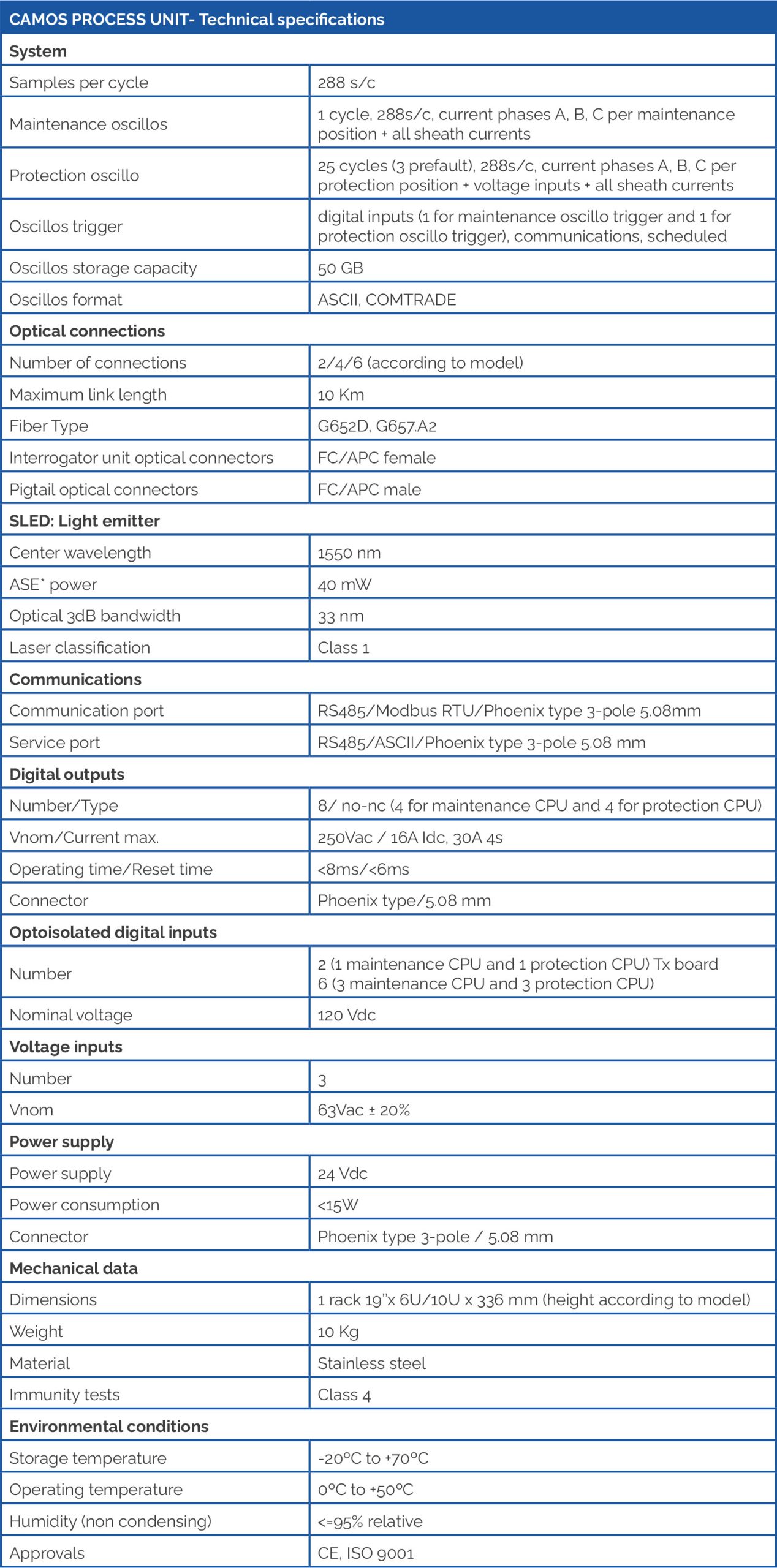

The CAMOS system monitors in real time the most important variables of the cable, by defining in CAMOS Interface (our visualization tool) the stress-free operation areas for the cable. This way the cable operator can extend the life of the cable if it is operated within these established comfort zones.

Deloitte Report

Solutions for the monitoring and digitalisation of high voltage underground networks

CAMOS Components

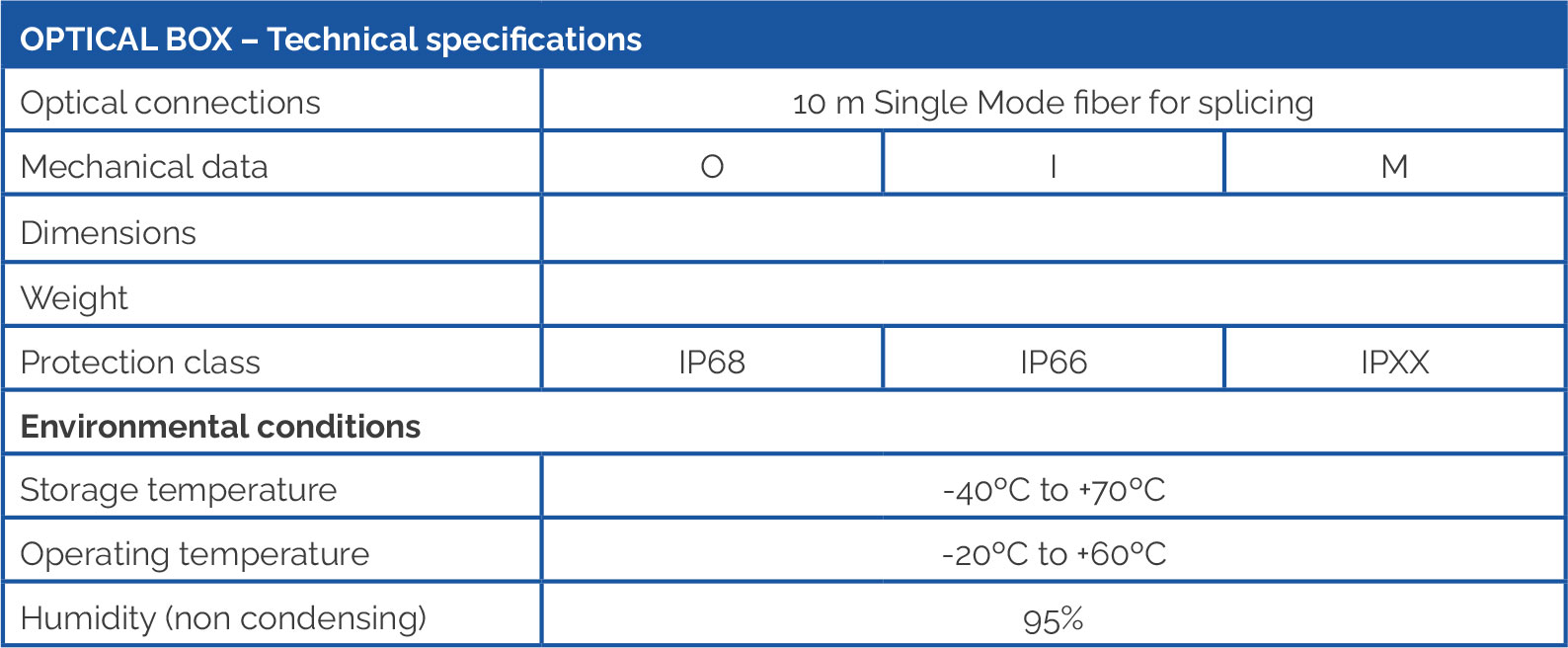

CAMOS is a system that allows the remote acquisition of current, without the use of power supplies or communications to transfer information using single-mode optical fibers, which are available for communication services.

These are the CAMOS system components:

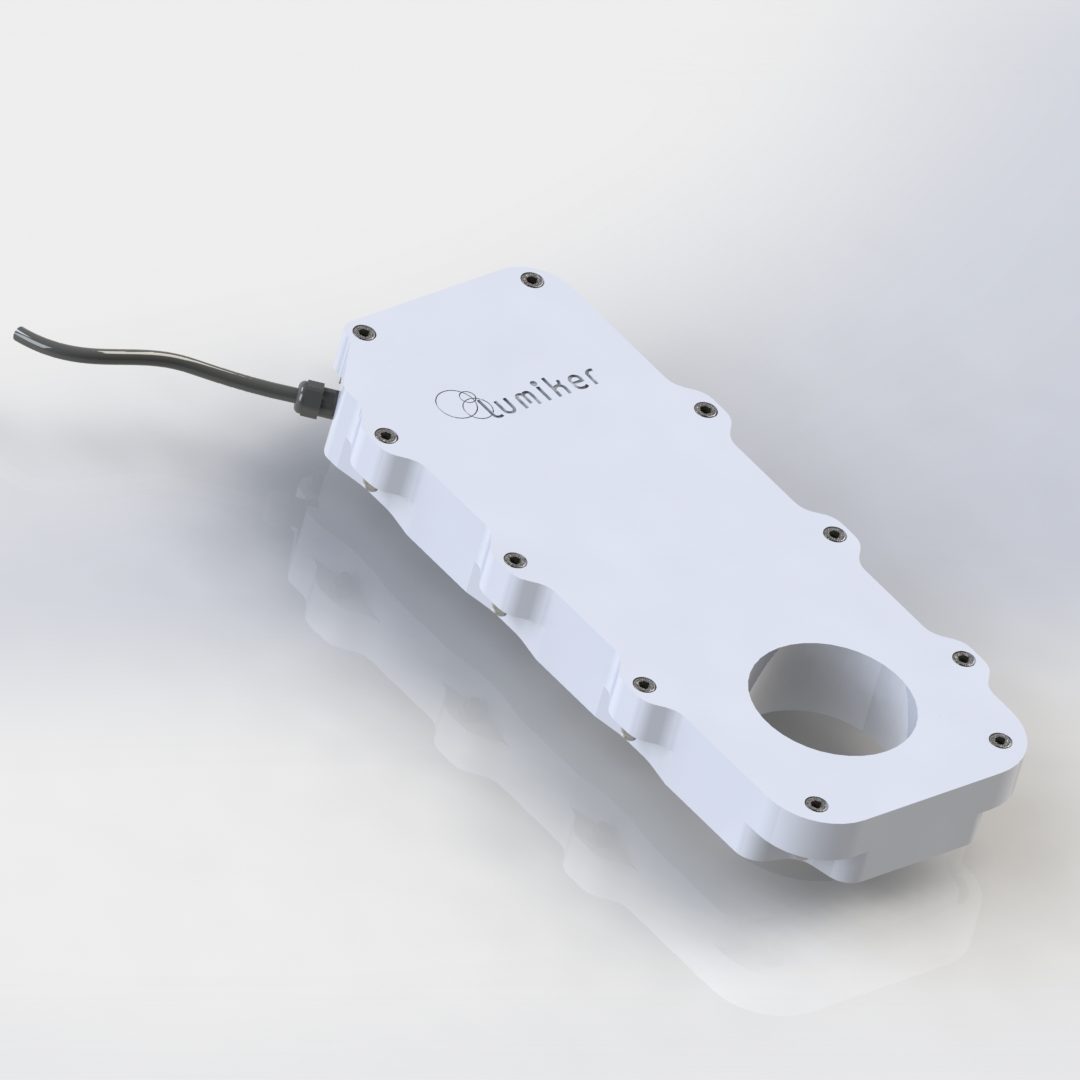

Our screen current transformers use fiber optics and are passive systems that do not require power. Once the light reaches the signal transformer, it is sensitive to the magnetic field generated by the current in the cable, modifying the polarization of the light that reaches our interrogator.

Our transformers are factory tested and calibrated. Screen transformers include a third winding for short circuit current reading (>60KA).

They use simple single-mode fiber for communications.

Installation is simple and can be done by any fiber optic communications subcontractor.

Our transformers:

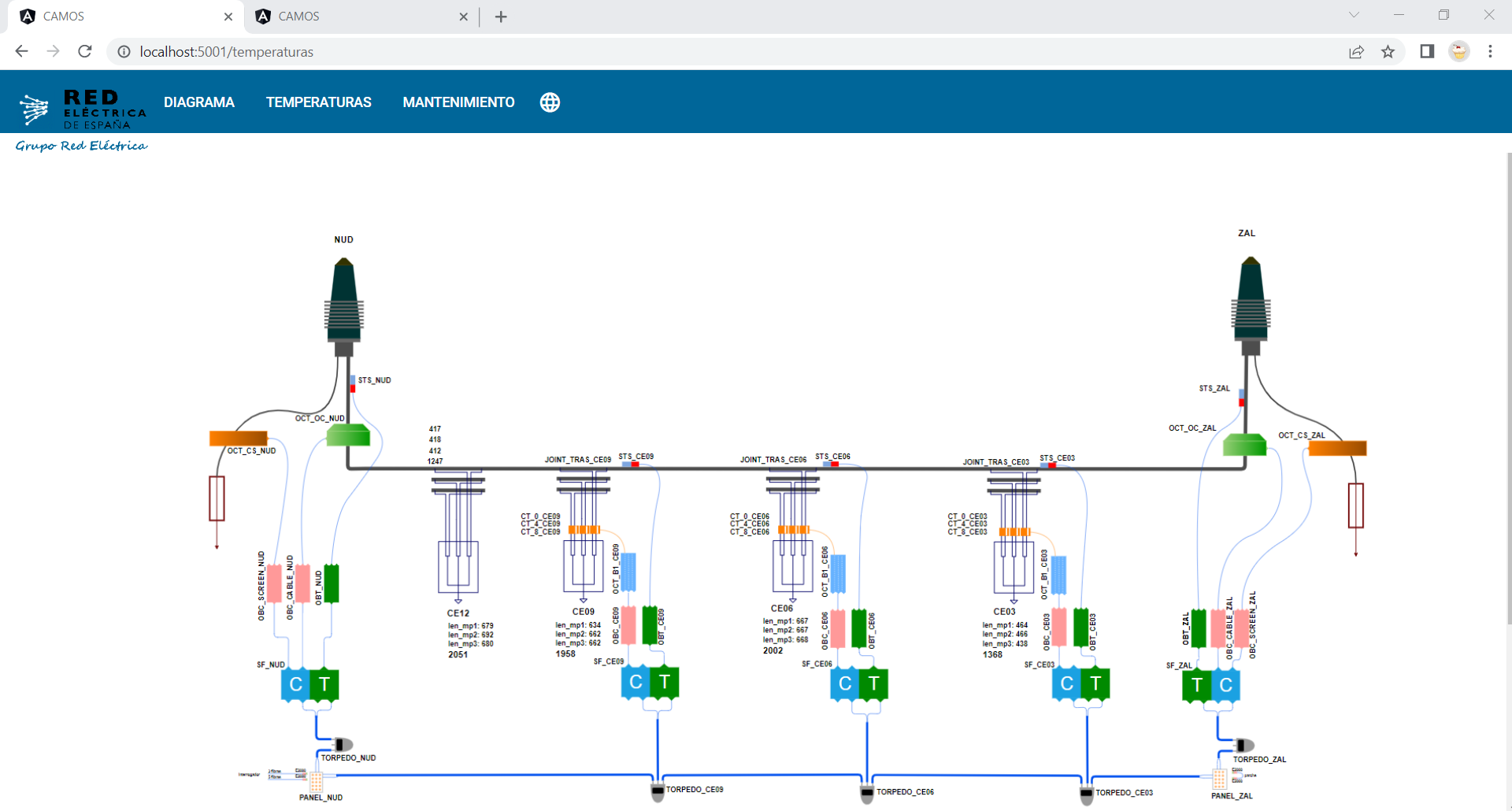

CAMOS Interface

CAMOS Interface is a real-time visualization and measurement application where our customers can monitor:

It continuously monitors the cable operations detecting stress situations allowing to extend the cable lifecycle.